Are glass jars renewable? Whether you are an environmentalist or not, you may be concerned about this issue. As a senior glass jar manufacturer and supplier in China, we will analyze it in detail from the following aspects.

The production process of glass jars can be summarized into six steps:

1. Gather and mix raw materials:

The main raw materials used in the production of glass jars are sand (silica), soda ash (sodium carbonate), limestone (calcium carbonate) and other additives. These materials are measured and mixed in proportions to form the glass batch.

2. Melt the glass batch:

The glass batch is heated in a furnace at high temperatures, typically around 1500°C (2732°F). The heat causes the raw materials to melt and form a molten glass mixture.

3. Forming of glass jars:

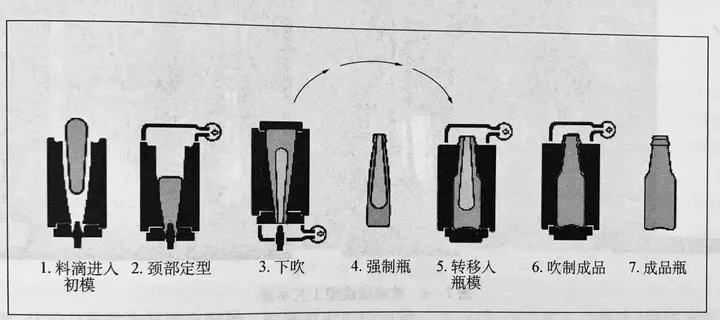

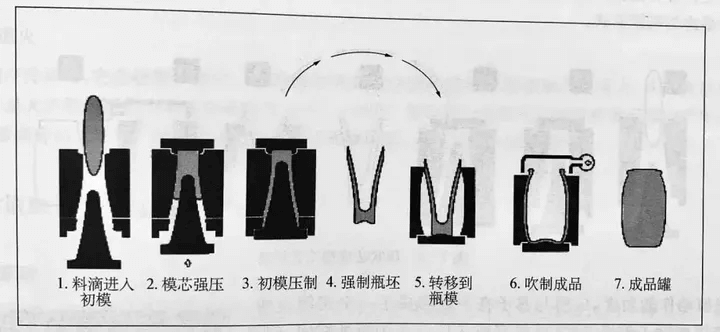

The melted mixture can be formed into any shape of glass jar using the following two methods with a customized mold. There are currently two main processes for the production of glass bottles and jars: the blow-blow method for narrow bottle mouths and the pressure-blow method for larger diameter bottles and jars.

1) Blowing method: This method is typically used for smaller glass jars. A glass blower or machine blows air into the mass of molten glass at the end of the blowpipe, creating a hollow shape. The glass is then transferred to molds for further shaping and cooling.

2) Pressure Blowing: This method is typically used for larger glass jars. The molten glass mixture collects on an iron plunger and is forced into the mold cavity. The glass is then shaped by pressing it against the sides of the mold and blowing air into it to create the desired shape.

4. Annealing:

After the glass jar is formed, it goes through a process called annealing. The jar is gradually cooled in a controlled manner to remove internal stress and make the glass stronger. Uneven cooling and rapid cooling cause stress in the glass, which can cause the glass to become brittle or explode. The function of the annealing furnace is to heat glass bottles and jars to about 580°C, and then slowly cool them to relieve the stress generated during glass molding and ensure the safety of the glass containers. This annealing process depends on the glass thickness and generally takes 20 - 60 minutes.

5. Finishing: After the glass jar is annealed and cooled, various finishing processes will be performed. These processes may include trimming excess glass, applying decorative elements or labels, and checking for quality control.

6. Packaging and Distribution: Pack the finished glass jars and prepare them for distribution. They can be stacked, packaged or placed in boxes or pallets for transport to the intended destination. Of course, this is just a glass jar. Compared with the various types of glass packaging products that everyone sees in life, the surface processing technology of the glass jar will also be carried out, such as screen printing, labeling and other customized processes to meet the end customer's needs.

From the above introduction, you can see that as long as there are sufficient raw materials, glass jars can be continuously reproduced, and the materials for glass jars are almost inexhaustible. However, energy support and environmental protection are involved in the production process. question. The following will introduce to you today, with serious environmental issues, whether glass jars can be recycled and reused after use ?

From a personal perspective, waste glass jar packaging can be cleaned and reused to make various handmade gadgets, such as storage jars, vases, candle jars, lampshades, decorations, flower pots, etc.

From a social perspective, large quantities of recycled glass jars are sorted, cleaned, crushed, and melted, and then used as raw materials to make new glass bottles and jars. Glass fiber materials, glass brick building materials and roadbed filling materials can also be manufactured to prevent landfill from being unable to degrade and polluting the environment.

Glass is made of sand, soda ash and limestone, and the beaches and deserts on the earth are covered with endless sand, and new sand is constantly being generated under the erosion of water and wind. In terms of raw materials, there is an infinite amount. It’s just that the manufacturing process of glass jars requires the support of energy and resources. In addition to coal, oil and natural gas, there are also new energy sources that are constantly being developed, such as solar energy, wind energy, biomass energy, geothermal energy, water energy and ocean energy. Moreover, products packaged in glass jars can be reused due to their durability, reducing waste and pollution. So unlimited raw materials, efficient recycling systems and consumer recycling awareness help maximize the renewable potential of glass jars and minimize environmental pollution.

Finally, as a manufacturer and supplier of glass packaging, HUIHE always adheres to the production and sales of high-quality glass jars, making glass packaging products more durable and more conducive to recycling.

What types of glass jars are produced and sold by HUIHE ?

At present, our company's main glass jar products include 13 major series and thousands of varieties of glass products, including glass food jars, glass storage jars, glass candle jars, spirit bottles and glass beverage bottles , with an annual output of 350 million pieces.

|  |  |

| glass food jars | liquor bottle | beverage glass bottle |

The company also has 6 deep processing workshops, which can provide customers with services such as frosting, trademark printing, inkjet printing, silk screen printing, engraving, polishing, and cutting, achieving "one-stop" service.

Our products have passed SGS, RoHS, CE, ISO and other certifications and enjoy a high reputation in the global market. Products are exported to more than 30 countries and regions including the United States, Canada, Europe, Australia, Southeast Asia, and the Middle East.

High-quality products, factory prices, and worry-free service are our company's business philosophy. We hope that with our nearly twenty years of industry experience and professional service team, we can help your company continue to grow with us.

If you have any inquiries, please send us an inquiry and we will do our best to serve you!